Personalized Stroller Cup Holder – 3D-Printed for Maximum Comfort and Long-Lasting Use

Sometimes even the simplest needs are hard to meet with off-the-shelf products. That’s exactly the situation my client faced — they needed a cup holder for a baby stroller that was no longer available for purchase. So I offered a custom design and 3D printing solution.

From Idea to Model

The client provided me with the original, broken cup holder. Based on that, I was able to get to work quickly. Instead of replicating the original 1:1, I decided to improve it — focusing on better ergonomics, durability, and user comfort.

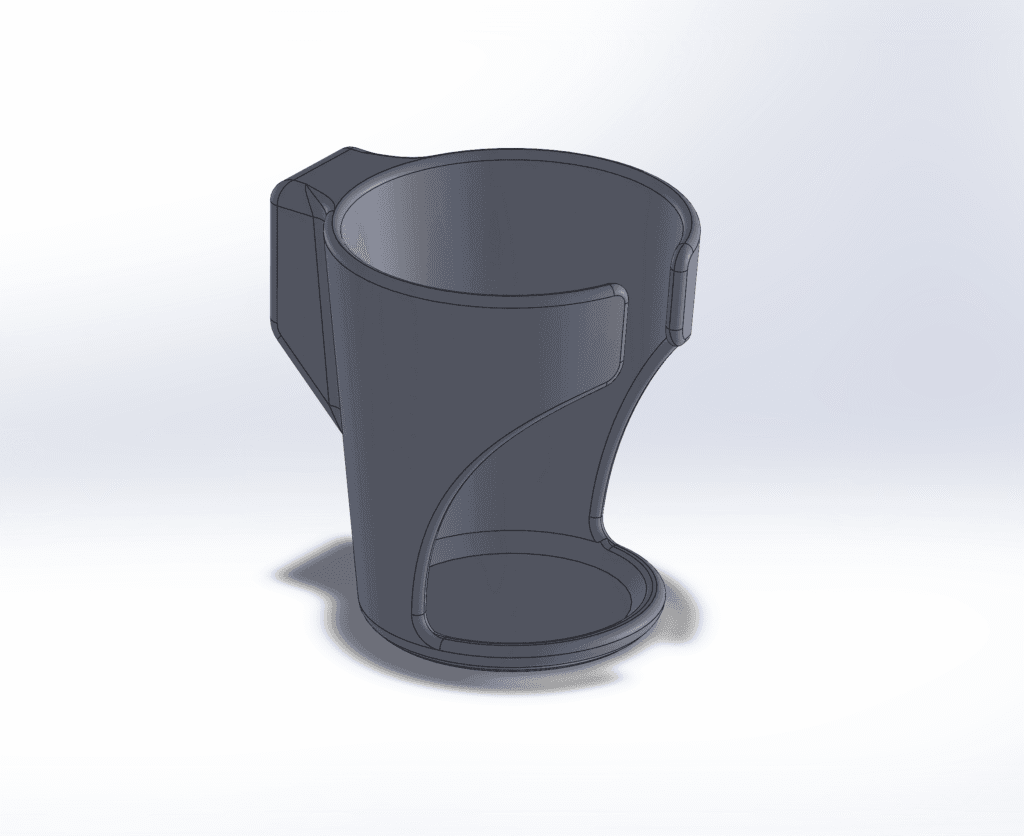

Using SolidWorks, I designed a new holder that’s both lightweight and stable. Every detail mattered: the mounting method, fit for the cup’s diameter, and the overall usability. Thanks to the digital 3D model, we could accurately predict how the holder would perform in real use.

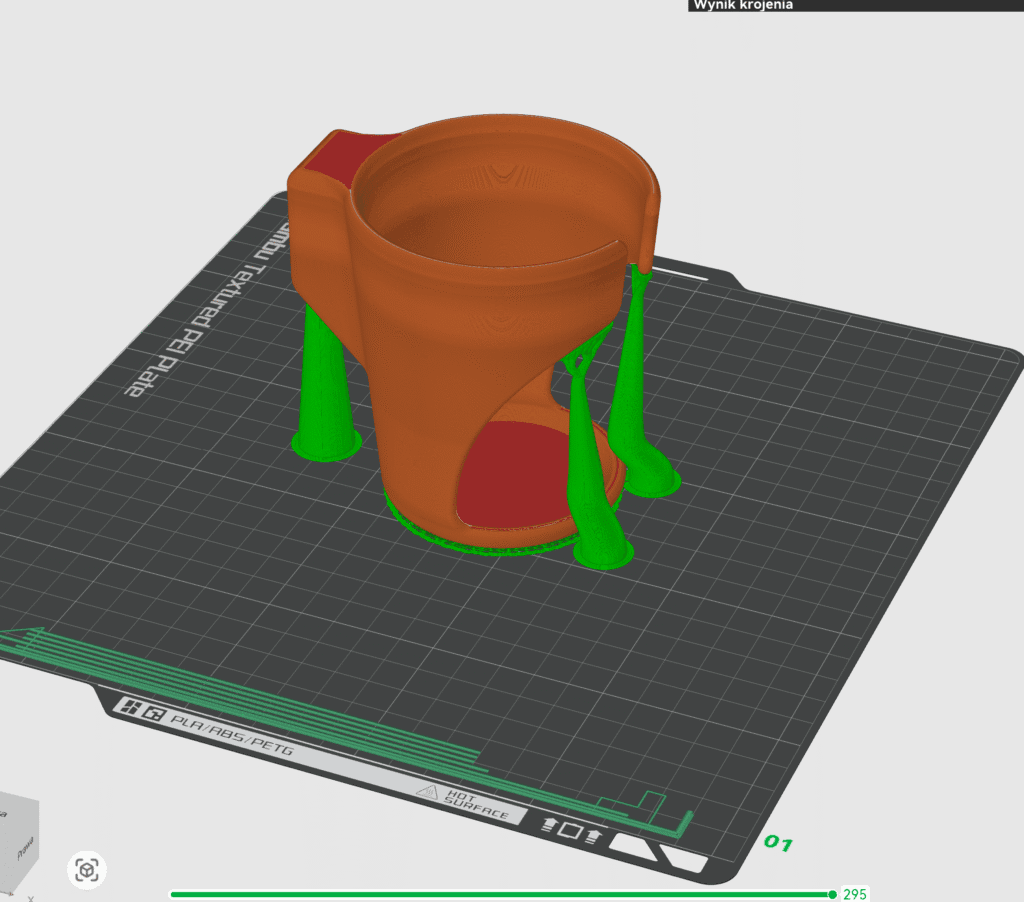

Preparing for 3D Printing

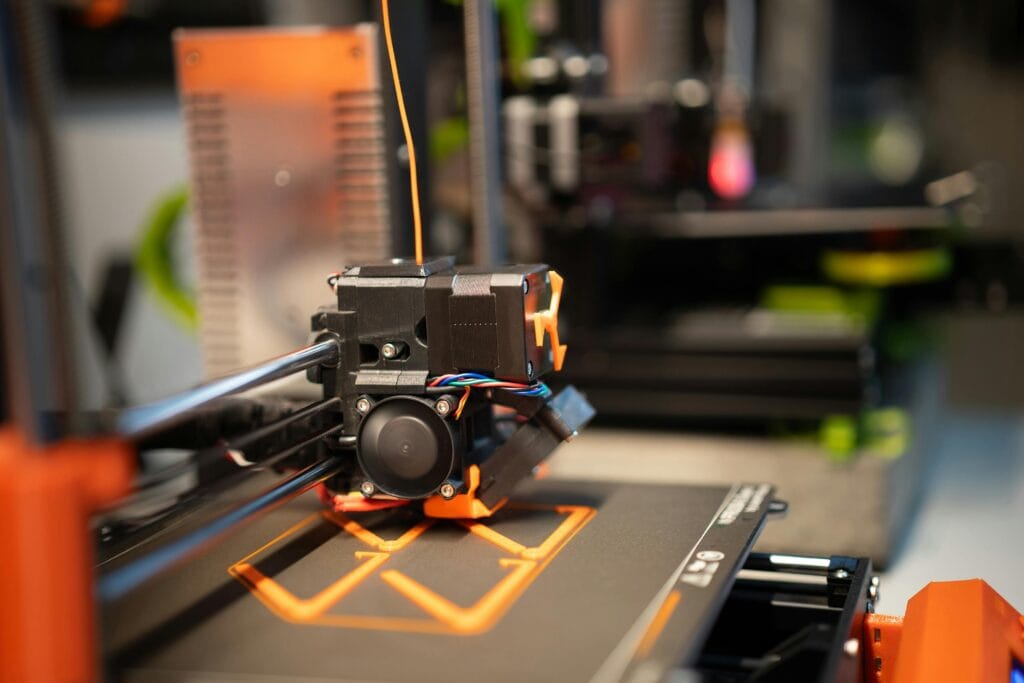

Once the model was complete, I exported it as an STP file and optimized it for 3D printing. The first version was printed using PLA-CF filament (carbon fiber reinforced PLA). This material offers excellent stiffness and surface finish, making it ideal for a test print.

However, the final version is planned to be made of PETG, which performs better when exposed to moisture, UV radiation, and temperature fluctuations. This is important since the cup holder will be used outdoors — in various weather conditions. As a result, the final part will not only be well-fitted but also much more durable.

The printing process went smoothly. The settings were adjusted to ensure a smooth surface and high functional strength. The finished holder was ready for immediate test fitting.

Final Result

After a quick clean-up, the holder was ready to be delivered to the client. The new part not only replaced the original but also improved overall user comfort.

In Conclusion

This project is a great example of how 3D printing enables tailored, practical solutions — quickly, precisely, and without unnecessary compromises. Most importantly, the damaged original part wasn’t an obstacle. Thanks to accurate measurements, I was able to create something perfectly suited to the user’s needs.

If you’re facing an unusual problem and need a custom solution — feel free to reach out. I’d be happy to help design and produce a part that simply works.